Rigtec can offer a complete engineering service. We pride ourselves on our abilities to offer design, solutions for repairs and the manufacture of components/items for all types of industry.

Rigtec is driven, by the recognition that in today’s business environment we need to be a cost effective engineering facility that can deliver products on time.

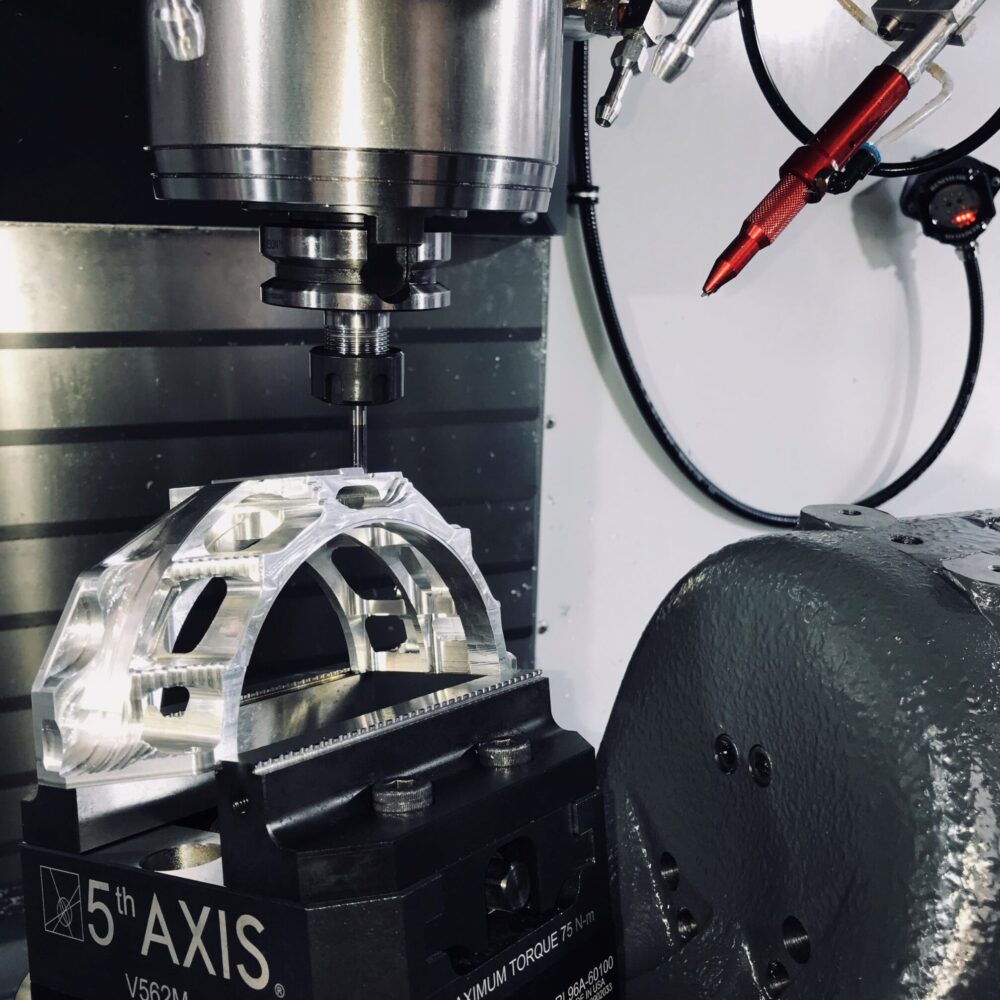

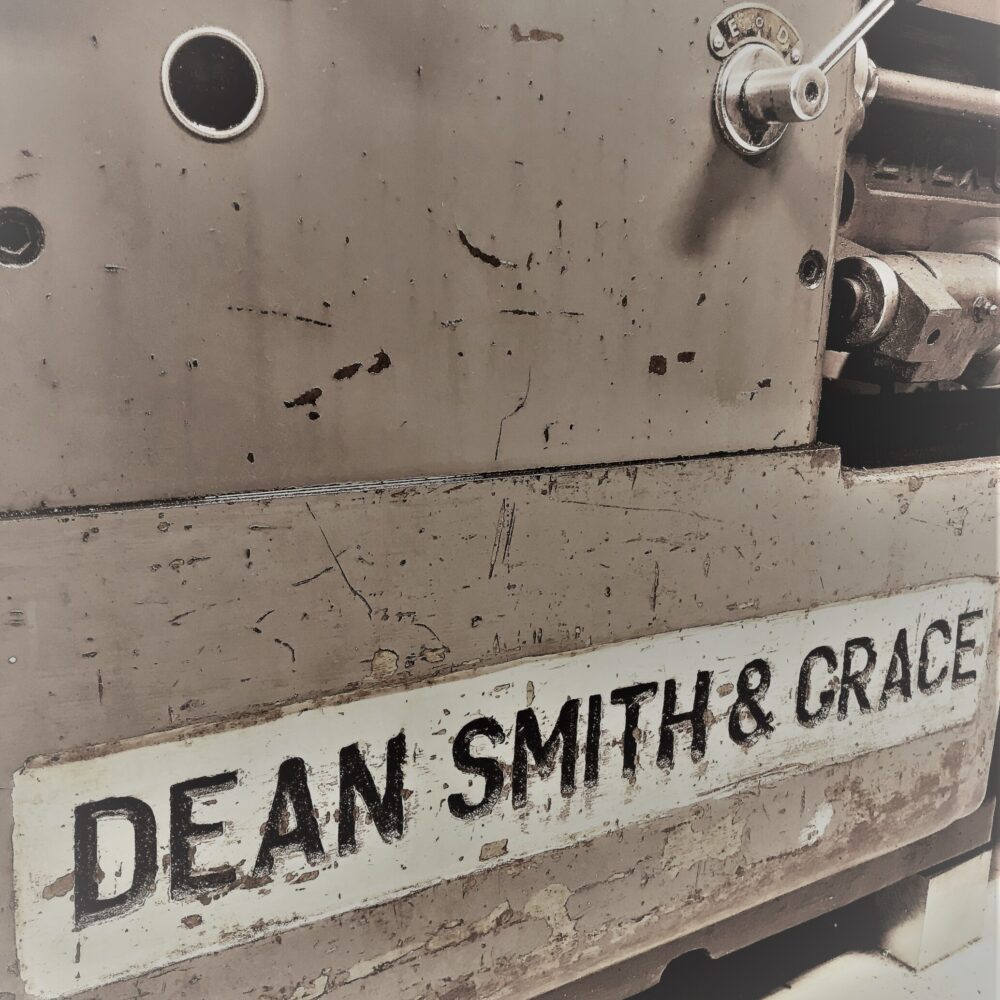

We have the capability to produce items cost effectively, machine one off components and build mass item production runs with CNC machining

- CNC Machining Centre

- CNC Lathe

Email: info@rigtec.co.nz